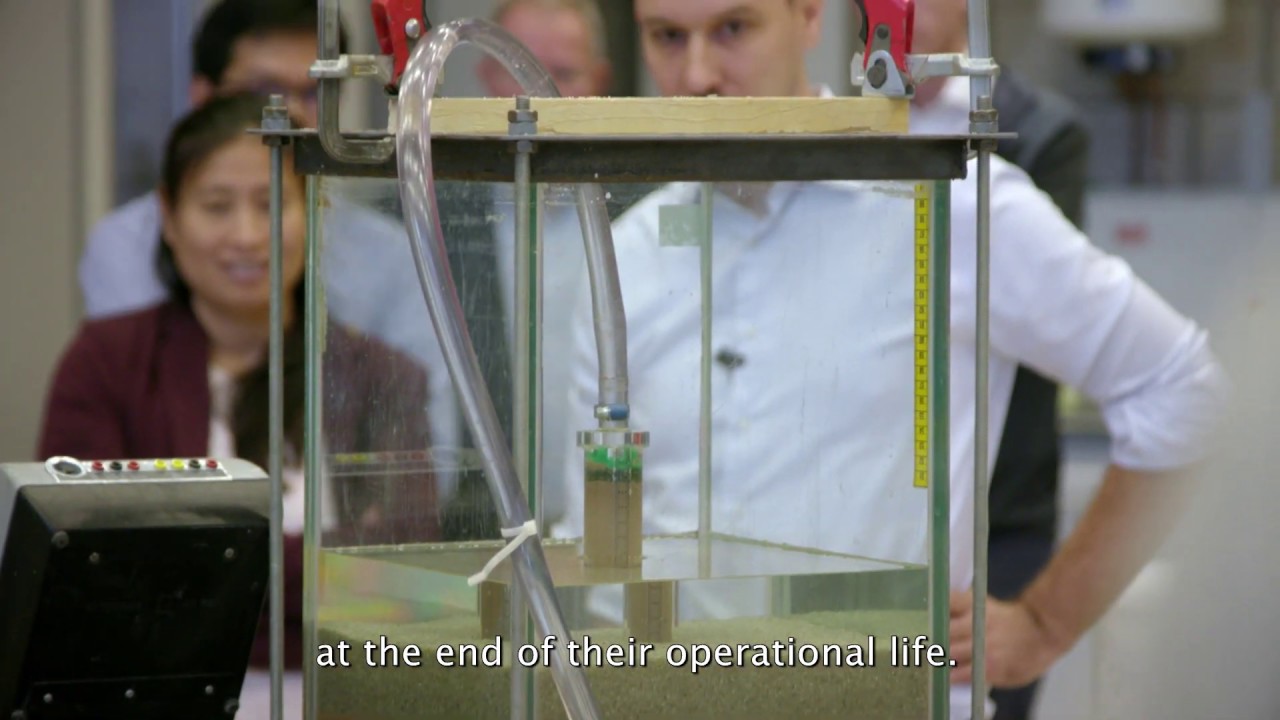

Several offshore wind farms are at the end of their lifespan and more and more of them will be decommissioned in the next two or three decades. To remove the monopiles in a sustainable and cost-effective way, new techniques are being developed. Hydraulic extraction of monopiles is one of the new methods for removing the entire monopile. This contributes to a more circular economy, especially as all the steel can be recovered and recycled. Moreover, the method is expected to be more cost-effective compared to current techniques. Recently, this technique was tested at scale by partners of the GROW consortium within the HyPE-ST project at Deltares in Delft.

The Hydraulic Pile Extraction - Scale Tests (HyPE-ST) project focused on both the fundamental understanding and demonstration of the feasibility of hydraulic extraction of monopiles. The project is a one-year R&D joint industry project carried out within the GROW research programme.

Before this extraction technique can be safely and efficiently applied at full scale, a better understanding of the interaction between the pile and the soil before and during the extraction process must be obtained. Possible leakage of fluids under pressure must be minimised and an understanding of how much force is required to remove the pile must be obtained. Full-scale scale tests are therefore a prerequisite for the application of this technique. That is the main objective of this project.

The technique

The extraction technique involves sealing the monopile after removing the upper structure of the wind turbine and pressurising a liquid (water) into the void. This will push the stack upwards. The pressure exerted by the hydraulic pressure must be sufficient to overcome the frictional resistance forces along the shaft of the monopile. This break-up pressure depends on various factors such as soil type, size of the monopile, permeability of the soil, its strength, among others.

Benefits

Recent experience of limited decommissioning of offshore wind turbines has shown that the difficulties of cutting underwater and below the seabed are often underestimated. External cuts require adapted equipment, such as clamped frames and guide rails, to support the cutting tool. As for internal cuts, off-the-shelf cutting tools from the oil and gas industry can only be used to a limited extent, as the diameters of monopiles for wind turbines continue to increase. More importantly, any cut below the level of the local seabed requires excavation to make the level of the cut accessible to the cutting tool.

A removal method that requires neither an excavation nor any cut of the foundation structure could be significantly cheaper than partial removal of piles. This is due to narrower vessels and cranes and potentially fewer H&S groups as no diving operations are required. In addition, no part of the pile remains on site and the steel can be reused. Hydraulic extraction is one such method. This technique is more ecologically sustainable than partial pile removal. Not only because of the recycling element, but it also disturbs the soil less than cutting under the seabed. Therefore, hydraulic pile extraction contributes to a more circular economy and sustainable use of the seas.

Further development

The HyPE-ST project demonstrated the feasibility of the hydraulic extraction method for different soil configurations. The tests took place on piles 20 to 30 times smaller than regular monopiles. Promisingly, the tests proved the concept at lab scale. Now testing at larger or full scale is required. This is what the project partners are currently considering. Other interested parties may join them.

Projectpartners

HyPE-ST is coordinated by Innogy and includes six partners: Deltares, Delft Offshore Turbine B.V., IHC IQIP B.V., Jan de Nul, Sif Netherlands B.V., and TNO. The partners are research institutes, offshore contractors, an offshore wind project developer, a monopile manufacturer, and a wind turbine developer.

Access to the partners for the HyPE-ST project was facilitated by TKI Offshore Energy. Ahmed Elkadi, geotechnical engineer at Deltares, says: "This support, together with the financial support from TKI Offshore Energy and the Netherlands Enterprise Agency (RVO), was crucial for the HyPE-ST project."